01.What is "liquid cooling super charging"?

working principle:

Liquid-cooled super charging is to set up a special liquid circulation channel between the cable and the charging gun. Liquid coolant for heat dissipation is added into the channel, and the coolant is circulated through a power pump to bring out the heat generated during the charging process.

The power part of the system uses liquid cooling for heat dissipation, and there is no air exchange with the external environment, so it can achieve an IP65 design. At the same time, the system uses a large air volume fan to dissipate heat with low noise and high environmental friendliness.

02.What are the advantages of liquid cooling super charging?

Advantages of liquid cooling super charging:

1. Larger current and fast charging speed. The output current of the charging pile is limited by the charging gun wire. The copper cable inside the charging gun wire conducts electricity, and the heat generated by the cable is proportional to the square value of the current. The greater the charging current, the greater the heat generated by the cable. It must be reduced. To avoid overheating, the cross-sectional area of the wire must be increased, and of course the gun wire will be heavier. The current 250A national standard charging gun generally uses 80mm2 cable. The charging gun is very heavy as a whole and is not easy to bend. If you want to achieve larger current charging, you can also use dual-gun charging, but this is only a stop-gap measure in specific situations. The final solution to high-current charging can only be charging with a liquid-cooled charging gun.

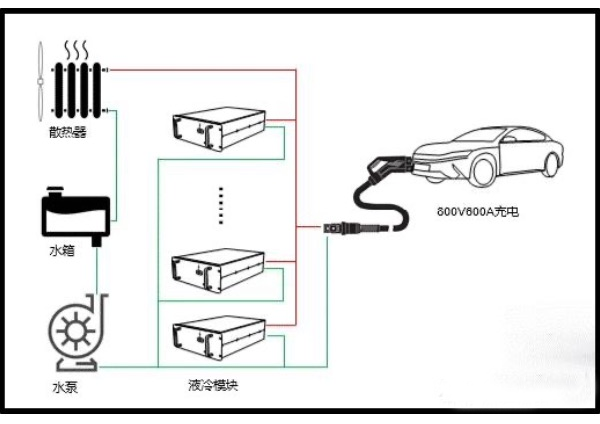

There are cables and water pipes inside the liquid-cooled charging gun. The cable of the 500A liquid-cooled charging gun is usually only 35mm2, and the heat is taken away by the flow of coolant in the water pipe. Because the cable is thin, the liquid-cooled charging gun is 30% to 40% lighter than a conventional charging gun. The liquid-cooled charging gun also needs to be equipped with a cooling unit, which consists of a water tank, water pump, radiator and fan. The water pump drives the coolant to circulate in the gun line, bringing the heat to the radiator, and then blowing it away by the fan, thereby achieving a larger carrying capacity than conventional naturally cooled charging guns.

2. The gun cord is lighter and the charging equipment is lightweight.

3. Less heat, fast heat dissipation, and high safety. The pile bodies of conventional charging piles and semi-liquid-cooled charging piles are air-cooled for heat dissipation. The air enters the pile body from one side, blows away the heat of the electrical components and rectifier modules, and dissipates from the pile body on the other side. The air will be mixed with dust, salt spray and water vapor and adsorbed on the surface of internal devices, resulting in poor system insulation, poor heat dissipation, low charging efficiency, and reduced equipment life. For conventional charging piles or semi-liquid cooling charging piles, heat dissipation and protection are two contradictory concepts. If the protection is good, the heat dissipation will be difficult to design, and if the heat dissipation is good, the protection will be difficult to deal with.

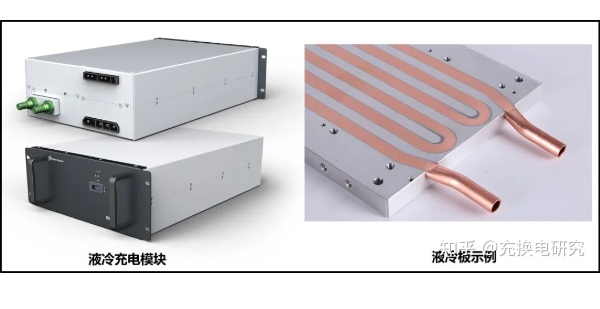

The fully liquid-cooled charging pile uses a liquid-cooled charging module. There are no air ducts on the front and back of the liquid-cooled module. The module relies on the coolant circulating inside the liquid-cooled plate to exchange heat with the outside world. Therefore, the power part of the charging pile can be fully enclosed to reduce heat dissipation. The radiator is external, and the heat is brought to the radiator through the coolant inside, and the external air blows away the heat on the radiator surface. The liquid-cooled charging module and electrical accessories inside the charging pile have no contact with the external environment, thus achieving IP65 protection and higher reliability.

4. Low charging noise and higher protection level. Conventional charging piles and semi-liquid-cooled charging piles have built-in air-cooled charging modules. The air-cooled modules are built with multiple high-speed small fans, and the operating noise reaches more than 65db. There are also cooling fans on the charging pile body. Currently, charging piles using air-cooled modules When running at full power, the noise is basically above 70dB. It has little impact during the day but is very disturbing at night. Therefore, the loud noise at charging stations is the most complained-about problem for operators. If complained, they have to rectify the problem. However, the rectification costs are high and the effect is very limited. In the end, they have to reduce the power to reduce the noise.

The fully liquid-cooled charging pile adopts a dual-cycle heat dissipation architecture. The internal liquid-cooling module relies on a water pump to drive the coolant circulation to dissipate heat, and transfers the heat generated by the module to the fin radiator. The external heat dissipation is achieved by low-speed high-volume fans or air conditioners. The heat is dissipated from the device, and the noise of the fan with low speed and large air volume is much lower than that of the small fan with higher speed. Fully liquid-cooled super-charged piles can also adopt a split heat dissipation design. Similar to a split air conditioner, the heat dissipation unit is placed away from the crowd, and it can even conduct heat exchange with pools and fountains to achieve better heat dissipation and lower costs. noise.

5. Low TCO

The cost of charging equipment at charging stations must be considered from the full life cycle cost (TCO) of the charging pile. The life of traditional charging piles using air-cooled charging modules generally does not exceed 5 years, but the current lease period for charging station operations is 8-10 year, which means that the charging equipment needs to be replaced at least once during the station's operating cycle. On the other hand, the service life of fully liquid-cooled charging piles is at least 10 years, which can cover the entire life cycle of the station. At the same time, compared with charging piles using air-cooled modules that require frequent cabinet opening, dust removal, maintenance and other operations, fully liquid-cooled charging piles only need to be flushed after dust accumulates in the external radiator, making maintenance simple.

The TCO of a fully liquid-cooled charging system is lower than that of a traditional charging system using air-cooled charging modules, and with the widespread mass application of fully liquid-cooled systems, its cost-effectiveness advantage will become more obvious.

03. Market status of liquid cooling super charging

According to the latest data from the China Charging Alliance, there were 31,000 more public charging piles in February 2023 than in January 2023, a year-on-year increase of 54.1% in February. As of February 2023, member units within the alliance have reported a total of 1.869 million public charging piles, including 796,000 DC charging piles and 1.072 million AC charging piles.

In fact, as the penetration rate of new energy vehicles continues to increase and supporting facilities such as charging piles develop rapidly, the new technology of liquid-cooled supercharging has become the focus of competition in the industry. Many new energy vehicle companies and pile companies have also begun to carry out technology research and development and layout of overcharging.

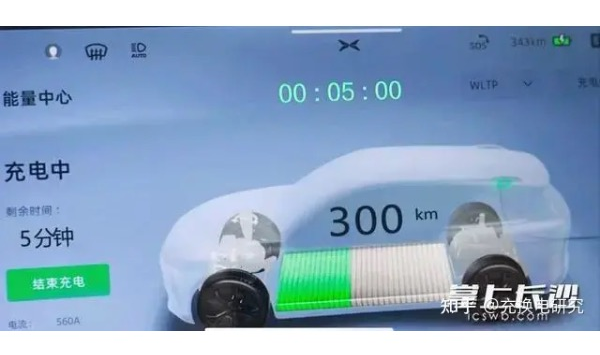

Tesla is the first car company in the industry to deploy liquid-cooled supercharging piles in batches. Currently, it has deployed more than 1,500 supercharging stations in China with a total of 10,000 supercharging piles. The Tesla V3 supercharger adopts a fully liquid-cooled design, a liquid-cooled charging module and a liquid-cooled charging gun. A single gun can charge up to 250kW/600A, which can increase the cruising range by 250 kilometers in 15 minutes. The V4 model is about to be deployed in batches. The charging pile also increases the charging power to 350kW per gun.

Subsequently, Porsche Taycan launched the 800V high-voltage electrical architecture for the first time in the world and supports 350kW high-power fast charging; the Great Wall Salon Mecha Dragon 2022 global limited edition has a current of up to 600A, a voltage of up to 800V, and a peak charging power of 480kW; GAC AION V, with a peak voltage of up to 1000V, a current of up to 600A, and a peak charging power of 480kW; Xiaopeng G9, a mass-produced car with an 800V silicon carbide voltage platform, suitable for 480kW ultra-fast charging;

04. What is the future trend of liquid cooling super charging?

The field of liquid cooling overcharging is in its infancy, with great potential and broad development prospects. Liquid cooling is an excellent solution for high-power charging. There are no technical problems in the design and production of high-power charging pile power supplies at home and abroad. It is necessary to solve the cable connection from the high-power charging pile power supply to the charging gun.

However, the penetration rate of high-power liquid-cooled supercharged piles in my country is still low. This is because liquid-cooled charging guns account for a relatively high cost, and fast charging piles will usher in a market worth hundreds of billions in 2025. According to public information, the average price of charging piles is about 0.4 yuan/W. It is estimated that the price of a 240kW fast charging pile is about 96,000 yuan. According to the price of the liquid-cooled charging gun cable in the CHINAEVSE press conference, which is 20,000 yuan/set, the cost of the liquid-cooled charging gun is estimated. Accounting for approximately 21% of the cost of charging piles, it becomes the most expensive component after charging modules. It is expected that as the number of new energy fast-charging models increases, the market space for high-power fast-charging piles in my country will be approximately 133.4 billion yuan in 2025.

In the future, liquid cooling super charging technology will continue to accelerate penetration.

The development and layout of high-power liquid-cooled overcharging technology still has a long way to go. This requires the cooperation of car companies, battery companies, pile companies and other parties. Only in this way can we better support the development of China's electric vehicle industry, further promote orderly charging and V2G, help energy conservation and emission reduction, low-carbon and green development, and accelerate the realization of "double Carbon" strategic goal.

Post time: Mar-04-2024